Asger Lauritsen is a Group Executive Management, Chief Procurement Officer – Supply Chain & Manufacturing at FLSmidth, having responsibility over end to end supply chain functions.

He has over 20+ years of operations, procurement, manufacturing, supply chain, innovation and project experience from large complex engineering, process and transportation companies. Having also previously held executive roles in Norden as double hatting CPO and CTO.

As well as several positions in Maersk, from general manager, to heading IT, operations and in his last role, being chief procurement officer FLSmidth is one of the leading suppliers of engineering, equipment and services to the cement and mining industries globally with more than 13,000 employees. Every year, they have 750K supplier deliveries and 250K customer deliveries.

Listen to the full discussion here:

Connect with the Guest:

Asger Lauritsen: LinkedIn

Some of the highlights from the podcast:

- What helped Asger navigate many different career, scopes of jobs and geographical locations

- Nearshoring trends around the world

- Reducing the no. of suppliers from 15,000 to 7,500, with 90% of the business belonging to just 1,400 suppliers. Challenges along the journey!

- Digitalisation, A.I. and ‘robots’. And how they are likely to replace the one system-wide systems from Oracle, SAP or similar.

- Sustainability and FLS target carbon neutrality by 2030 which is incredibly ambitious in that space.

Show notes:

- [1:12] You’ve done everything from running businesses and right now you have a very broad portfolio. Tell us a little bit about that and how it helps you be who you are now.

- [3:48] What are the certain inflection points in your career that cause the ability to switch like you did, from business to general management, sales, marketing and supply chain operations?

- [4:15] One thing, be curious, raise the finger, make yourself useful, work a lot with stakeholders and then really put the customer in the center.

- [8:05] Tell us a little bit about FLSmidth and how do you focus on making your services and your products sustainable?

- [8:12] We invest a lot each and every year in our research and development to develop more sustainable products. For the mild and severe, you can say I’m in the mining industry and it is moving into a growth cycle. Therefore, we also have to make sure that those mines are opening as sustainable as possible.

- [12:30] What are some of the criteria on how you select which one is better and how do you also do change management around getting the organization on board?

- [13:17] It’s multi-dimensional, the more you can standardize and modernize your products and service offerings the better because that also makes it easier for the supplier to contribute. And then really involve the suppliers, so it becomes a dual process.

- [14:47] On the flip side, what are some of the challenges and biggest hurdles to overcome in this process?

- [15:03] One of the challenges is actually the IP landscape, the IT landscape, and we are a company that has been here for four years. It’s been a mix of organic growth and acquisitions and then you take all kinds of IT systems and maybe you’re not disciplined enough in making the needed changes and having one big IT system.

- [18:30] You mentioned that a big challenge was technology, right? How about the people’s mindset? What were some of the elements that may be challenging? And how did you come in?

- [19:56] Tell us a little bit more about nearshoring and how do you see it playing out in the next three to five years?

- [21:28] You see salary inflation rates both in India and in China. And obviously, the rates are not based on what rates are but the predictability of congestion is actually worse.

- [25:13] Where will your container rates return to normal?

- [25:20] I think things were normalized, I mean, spend sometimes on shipping and supply and demand tend to equalize.

- [25:48] What’s the most rewarding part of your job?

- [26:37] In general, no noise is good noise. When you have heavy customers, people are focused on their day to day business to deliver the promise, because on-time delivery is also a handshake, a promise that you get for our promise. That’s part of the experience that exists.

- [27:28] Looking back on your career, what would be one piece of advice that helped you the most and what would be one piece of wisdom that you would share?

- [27:36] Certainly, be curious, look for the things that are not working but always come forward with a solution and make yourself useful and then don’t be afraid of the unknown.

About the Host:

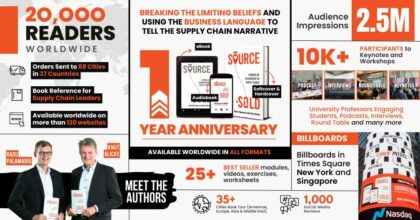

The host, Radu Palamariu is the co-author of “From Source to Sold – Stories of Leadership in Supply Chain”. He has been named one of the top 3 Global Supply Chain Influencers on LinkedIn and was featured in Forbes, Bloomberg, WEF, Bangkok Post, and MIT Supply Chain Talent magazine. Radu invites executives to share stories and perspectives around technology, logistics, e-commerce, supply chain, and manufacturing, and their views on how the future will look.

Alcott Global connects and upgrades the supply chain ecosystem by finding the right talent through executive search, developing talent through learning solutions, and meeting supply chain technology needs through a comprehensive crunch base marketplace.

The supply chain executive search has been our focus since the very beginning, offering recruitment services for top-tier supply chain roles at every level of the end-to-end supply chain: plan, source / procure, make, and deliver. Our consultants have years of experience in placing top talent, in North America, LATAM, Europe, the Middle East & Africa, and APAC, and besides speed, one of our biggest strengths is our network within the supply chain industry, and we capitalize on it to find the best solutions.

Through the years, we have grown as an organization and our offerings with it. One of our initiatives, the learning solutions- training and supply chain academy, is focused on transforming leadership- self-leadership, executive presence, influence capital, and business acumen. Through Supplify, we aim to match corporations with the top technology companies to solve their supply chain and logistics challenges with a focus on innovation and digital transformation.

We are in constant touch with the leaders in supply chain, inviting them to inspire the supply chain professionals in thought-provoking podcast episodes and events, and showcasing what is possible at the yearly Leaders in Supply Chain Awards.

Related Episodes:

#113: Emer Cunningham, VP Internal Medicine Global Supply Chain at Pfizer

#114: Susan Johnson, EVP Global Connections and Supply Chain at AT&T

#115: Tonya Jackson SSVP and Chief Product Delivery Officer of Lexmark